UltraPure Water Systems Designed for Optical Labs

Pure Water Works Installs and Services UltraPure Water Treatment Systems for the Largest Optical Labs Across the United States and North America.

Corporate ContactDI + RO Water Systems for Optical Labs

We design our systems around the lab’s specifications and requirements. Our systems are designed to grow.

Our PCZ Water Treatment Systems provide UltraPure water to optical labs that need Reverse Osmosis and Deionized Water for their processes. Pure Water Works combines reverse osmosis with deionization filtration process to create the purest, cleanest water for your Lab. These systems have incredibly efficient resin and they are by far the most economical way to achieve UltraPure quality water. These systems make the water 1,000x cleaner than a surgical laboratory and they are fully customizable to your lab. Units are custom-designed and built in our production facility in Traverse City, Michigan. Units are shipped out on a skid, with a technician following to install equipment and train the customer on the system’s use and maintenance. Pure Water Works is your source for your UltraPure water needs.

PCZ Series Systems

- PCZ L1300

- PCZ 380

- PCZ 760

- PCZ 1440

- PCZ 2880

- PCZ PurePH Neutralizer

Quick Facts

- Our systems produce 1 to 18.5 million ohms of resistance to ensure ultrapure water for your process.

- Our proprietary PCZ process uses a combination of multiple ultra-filtration methods including reverse osmosis, deionization (DI), and water softening that allow us to create ultra-high purity water while using less resin.

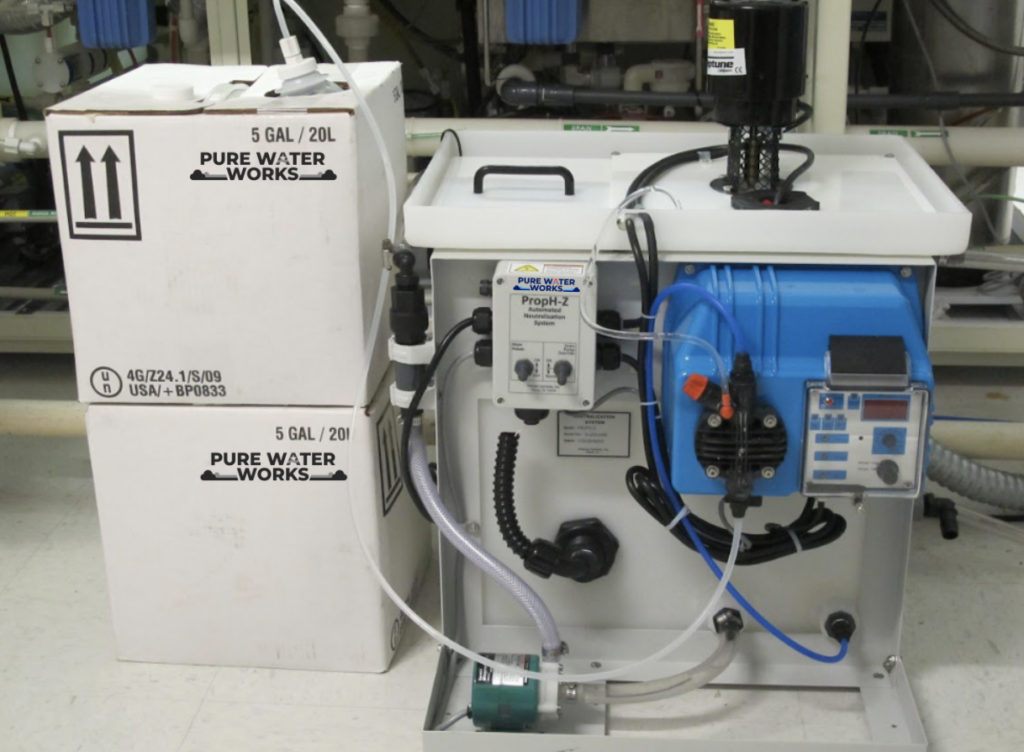

Pure-pH Alkaline Neutralization System

The Pure-pH automated neutralization system from Pure Water Works is designed to neutralize UltraSonic lens washer effluent, automatically monitor the pH and, when needed, dose the required neutralizer until the effluent meets the user-determined pH. Ensure your lab’s environmental compliance and automate your waste-neutralization process with a Pure Water Works Pure-pH.

- Proven reliable, extra-long-life pH sensor designed to automatically monitor and neutralize UltraSonic Lens Washer effluent to a user determined pH.

- Constantly measures pH of effluent in tank – Minimizes usage of neutralizer and operating costs

- Digital readout of pH provides constant monitoring of effluent pH

- Proportional pH controller automatically doses only the neutralizer necessary to reach set-point

- Automatically dispenses to drain only when pH is within acceptable limits

- Small footprint, 29”w x 22”d – Easy to install, operate and service

- High Flow Drain Pump flushes neutralized effluent out of tank to drain

Contact Us for a Custom Proposal

We design our systems around the lab’s specifications and requirements. Our systems are designed to grow. All systems have 5-stage ultrapurification: Pre treatment – 5-micron and CTO carbons, RO, DI, and UV.

Contact Us

OPTICAL SYSTEMS CONTACT US

Corporate & Industrial Contact Form

"*" indicates required fields